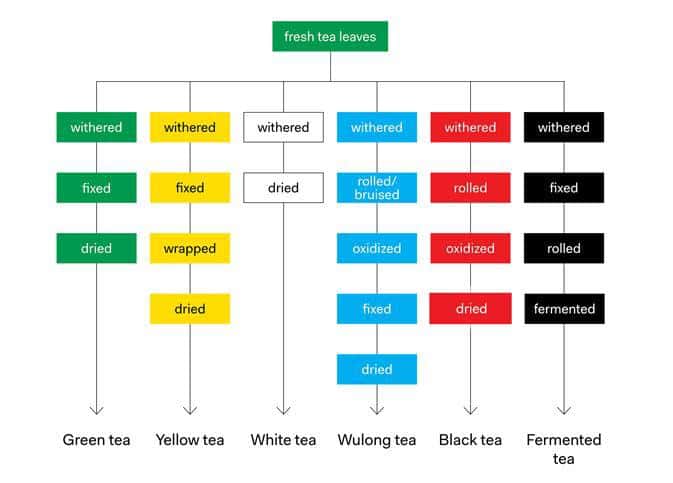

There are almost 3,000 varieties of tea, all completely different in look and taste, despite having been

derived from the same plant. The most scientific way of categorizing them is on the basis of the method of processing that the leaves have been put through. There are four main steps involved: withering, fixing, oxidation, and drying. Sometimes, the steps are interchanged or repeated, thereby creating a completely new variety.

Withering:

The process begins within an hour of harvesting. The fresh green tea leaves are wilted, by laying them on a wire mesh, under the sunlight for several hours. This reduces the moisture content, allowing the flavour compound, caffeine level, and antioxidants to develop. Darker the leaf, more intense the aromatic compounds. In the case of controlled withering, the leaves are laid down in troughs and treated with hot air. The amount of time that the leaves are withered, depends on the initial water content, and the desired flavour.

Firing/ Fixing/ Enzyme Kill Stage:

The leaves are exposed to high levels of heat for a short time period in order to halt enzymatic browning. This helps preserve the aroma and the antioxidant compounds. There are four commonly used methods-

Baking: The leaves are laid out on a conveyer belt and passed through an oven where they are baked. Steaming: Leaves are rotated through a metal cylinder that is flushed with steam, preserving the green color and vegetal taste of the leaves.

Pan-frying: The leaves are tossed around in a dry, hot wok by hand till they give out a nice, toasty flavour.

GABA: This technique was developed by Japanese researchers in 1987. By this process, the leaves are given a nitrogen treatment, which increases the gamma-Aminobutyric acid (GABA).

Leaf Maceration:

The leaves are physically broken down, causing biochemical changes that result in new flavours. There are four different stages:

Leaf Bruising: This process is used for oolong and sometimes, even black teas. Here, the leaves are shaken in a bamboo basket, or a machine, creating tears on the epidermis.

Rolling-Shaping: The leaves are processed so as to take shapes, such as the commonly seen needle or pearl leaves. The tighter the leaves are rolled, the longer they will retain their freshness.

Crushing: The leaves are cut into smaller pieces, resulting in a greater release of oxidation enzymes, compared to the previous methods.

Crush, Tear, and Curl (CTC): This method was developed in the 1930s. The leaves are put in a machine that crushes, tears, and curls them. By this method, exposed surface area of the leaves is increased, thus reducing the amount of tea required for brewing.

Oxidation:

This is the process that causes the tea leaves to brown, and unlocks news compounds at a molecular level, thereby increase the intensity of its flavour. This can happen in two ways:

Passive Oxidation: All the process they are subjected to, right from harvesting, exposes them to oxygen, resulting in several chemical reactions. This continues to take place till it is stopped by the enzyme kill stage.

Controlled Oxidation: External stimulus– a rise in room temperature, humidity, and breakage of the leaf’s epidermis–is introduced. To halt or slow down oxidation, the fermented leaves are moved to a panning trough where they are heated and then dried. This method allows tea makers to control the amount of oxidation the leaves go through, thereby being able to bring out specific intensities in flavors.

Drying:

The moisture content in the leaves is brought down to less than 1 percent enhance the flavour, as well as increase the shelf-life. The leaves are fried or roasted at a low temperature for a controlled period of time, typically inside an industrial scale oven.

Aging:

Sometimes, the leaves are subjected to aging and fermentation by storing them in dark, humid rooms, and exposing them to conditions which are conducive to microbiological activity and oxidation.